forklift lights safety - An Overview

forklift lights safety - An Overview

Blog Article

Mechanical malfunctions can be a Recurrent reason behind forklift accidents and personal accidents. Problems like leaky valves and hoses, worn-out or destroyed tires, and defective brakes can result in incidents.

OSHA establishes and enforces regulations and benchmarks targeted at safeguarding the welfare of workers and cutting down hazards.

Longterm reliability - Influence/corrosion-resistant polycarbonate lens and sealed housing for tough industrial environments

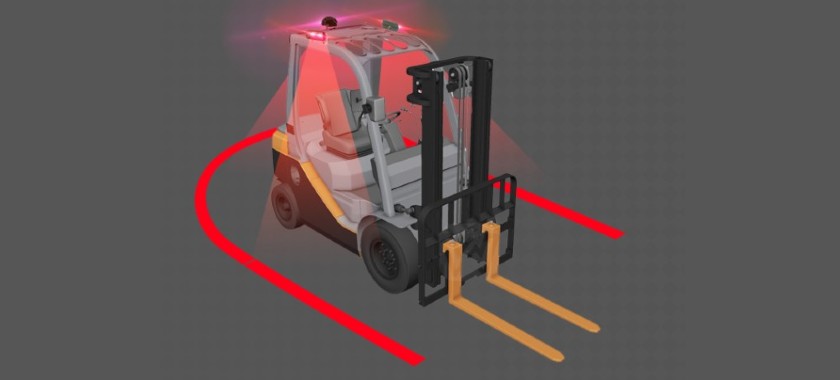

The primary reason of this projection is to determine a visible boundary or safety zone around the forklift. This seen boundary goes a long way in alerting men and women about approaching forklifts and assisting them manage a safe length.

The forklift beacon gentle, also called a strobe light-weight or warning beacon, is often a very visible flashing gentle affixed into the forklift's roof or other conspicuous areas.

Finding the correct elements in your tools is not difficult When you've got your design and serial variety which may be observed on the info plate. Thankfully, a forklift info plate is set up on every single truck available to help you understand what your forklift can perform and provide vital information and facts.

A blue warning light mounted about the again of a Toyota forklift Should you be a forklift driver, you may have observed these— blue lights. They are forklift lights safety generally often known as ‘safety lights’ because their design and style improves the safety of the region bordering a forklift truck.

Realistic schooling: Arms-on training for forklift forklift lights safety operators is crucial to acquire the necessary expertise. It requires dealing with a forklift beneath the assistance of forklift lights safety a professional instructor.

Operating situations occasionally need a lot more mild when moving and storing cargo. Nowadays, numerous forklift drivers are utilizing strobe lights when extra lights is required. Side-mounted warning lights give another option. OSHA encourages using strobe lights together with other State-of-the-art warning mild systems when desired.

Blue lights are integrated into forklifts to reinforce visibility and safety in busy operate Areas. These lights emit a brilliant blue beam that initiatives on to the ground, alerting pedestrians and nearby employees to your existence of the forklift.

Visible inspection: Operators need to inspect the forklift for virtually any visible indicators of harm, which include leaks or worn-out tires.

Much like the forklift arc light-weight, forklift lights safety the forklift blue spotlight serves the goal of creating a obvious warning zone across the forklift. It emits blue light-weight, outlining the forklift's perimeter and signalling its presence to Some others.

Blue safety lights, also referred to as blue spotlights, are set up within the overhead guard of a forklift. These lights task a concentrated blue beam on to the bottom in entrance or driving the forklift.

two LED lights with strong beam for each unit are long lasting. Multi-voltage able from 12V - 110V. Uses vehicle power to work. Gentle operates anytime forklift is turned on - forklift lights safety nobody should make sure to activate it